Personal hygiene as contamination control in pharma

Washing hands is an important practice, but beyond that, strict hygiene principles should be practiced in many industries, especially in the pharmaceutical sector, to protect against the risk factors associated with the drugs. One important aspect of this is personal hygiene in pharmaceutical industry, as workers remain the greatest potential source of contamination. By applying high hygiene standards to their personnel, the pharmaceutical industry can minimize contamination and cross-contamination risks and safeguard products and patients from further harm.

Why is personal hygiene important in contamination control?

Personal hygiene in pharmaceutical industry includes procedures and protocols that are essential in protecting products from microbes, particles, and any other physical contaminations brought by human workers into the controlled environment. It is also common for the human body to lose dust in the form of dead skin cells, hair, etc., and for human beings to carry non-pathogenic and other pathogenic microorganisms to sterile places. Where such practices are ignored, these contaminants are prone to get into the products and lead to safety and quality concerns.

Hygiene practices are important in every aspect of life, and in most cases, patients’ well-being is at stake whenever these practices are violated. Every employee is required to follow best practices, observe proper personal hygiene, and shield the product from contamination, as failing to do so may compromise the safety of the product when it comes to market.

Contamination and cross contamination risks in pharma

Anyone working in pharmaceuticals and medicine must understand the risks of contamination and cross contamination in pharma industry, as that is the only way to avoid them. Contamination is the introduction of foreign particles, microorganisms, or chemicals into the production process, which increases the risk and decreases the quality of the pharmaceutical product. Cross-contamination is said to occur when a particular product contaminates another product, usually unintended, and is often most serious in multi-product operations, such as pharmaceuticals.

Personnel are a major source of contamination and cross-contamination. Workers’ skin, hair, or even respiratory secretions can act as vectors for particulates. Furthermore, if the worker’s pattern of activity requires them to work in several different production areas without any cleansing in between, they could introduce cross-contamination within products or batches.

Personal hygiene practices to follow in pharmaceutical sector

Personal hygiene rules such as handwashing or greetings are included at every point of drug manufacture to lessen contamination risks. Some general hygiene measures can be mentioned as follows:

- Hand Hygiene: One of the easiest ways of avoiding the threat of contamination is performing adequate handwashing. Employees are expected to wash their hands thoroughly using effective antibacterial soap before entering the cleanroom areas, after touching the raw materials, and after any break. Many pharmaceutical facilities also require employees to apply alcohol foam, gel or liquid to their hands after washing them and prior to the start of work procedures.

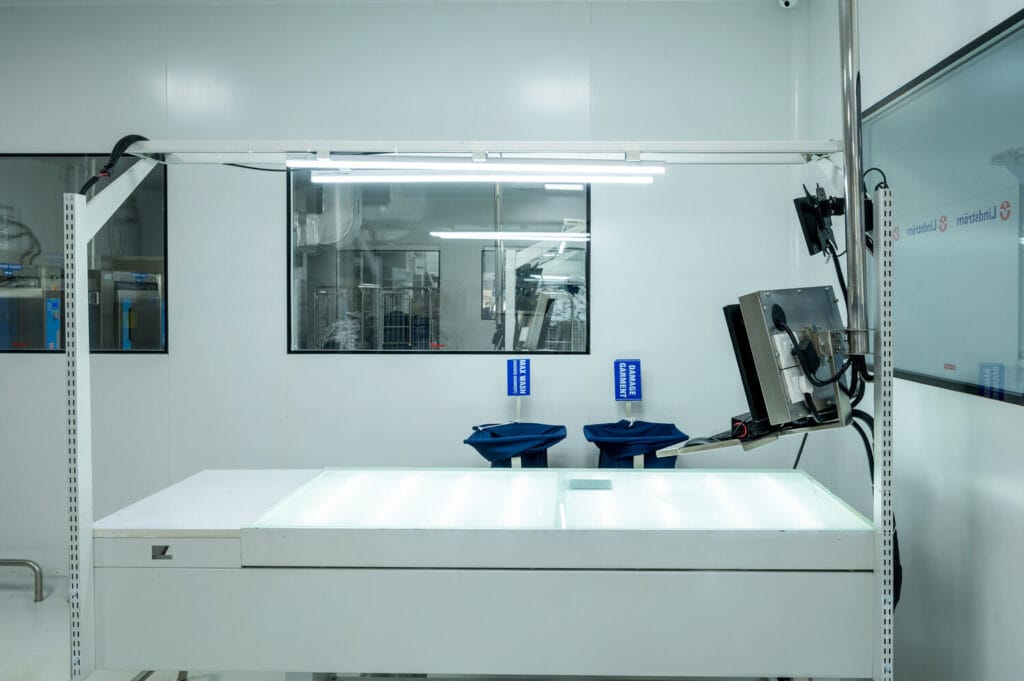

- Gowning and Cleanroom Attire: As it comes to cleanroom areas, it is obligatory for the workers to wear garments like cleanroom suits, and other accessories such as gloves, masks, and hair covers. Such garments act as insulators that help keep skin, head hair and other debris webbing away from contaminating the product. Donning and doffing garments is usually regulated to prevent contamination of the gowning uniform.

- Health Screening: Another crucial aspect of cleanliness is ensuring that workers are healthy and will not interfere with the production process in any way. Employees who have developed some symptoms of communicable illnesses like influenza illnesses, which include colds or coughs, should be blocked out of certain occupational areas which are sensitive to pathogen exposure to curtail the risk of employees transmitting the infections to the exposed. There are also regular check-ups and checks on employees, which helps reduce these breaches.

- No Jewelry or Personal Items: Wearing a cleanroom suit requires strict adherence to the removal of any jewellery and watches since they act as potential sources of contamination. Such items may produce dust or germ agents and contribute to contamination. All workers enter those areas devoid of those items.

- Regular Training: Enhancements can be realized from ongoing education and training. Workers should be informed on the practices of hygiene more often since their actions can affect the safety of a product. New employees should also be trained in the existing hygiene measures, and any new protocols implemented.

Conclusion

In the pharmaceutical sector, maintaining optimal levels of personal hygiene is the first line of defence in the fight against contamination and cross contamination in pharma production facilities. From the practicing of handwashing to the correct use of the gown, every hygienic activity has its place in safeguarding products in the pharmaceutical industry. Together with enhanced adherence to hygiene measures and personnel training, it is possible for businesses within the pharmaceutical sector to protect their businesses, achieve compliance, and, more importantly, shield the safety and health of customers.