Reinventing textiles

A new take on textiles

The textile industry is one of the world’s biggest polluters. Most textiles are still made for individual use, and later to be tossed, but that throwaway model is breaking down. Climate change, fast fashion, and mounting waste are pushing the industry to rethink how textiles are made, used, and renewed in our resource-scarce world.

At Lindström, we believe textiles can be both high-performing and responsible. Using smart technology, durable materials, and circular principles, we create textiles built to last for a better future.

Sustainability in the textile industry

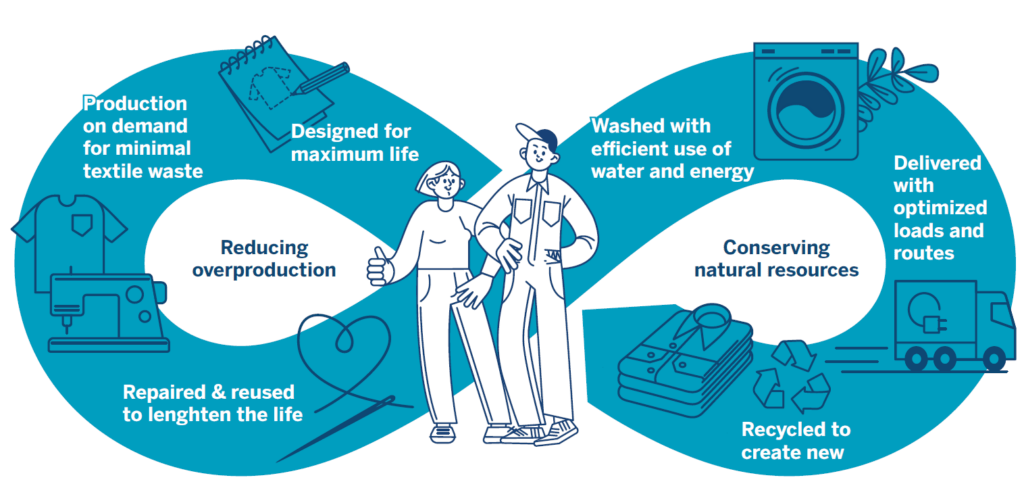

Sustainability is woven into every thread of our textiles. Our circular approach spans the entire lifecycle: designing with recycled materials, optimising washing processes to conserve water and energy, and recycling end-of-life textiles.

| The old way: Linear model | The new way: Circular model |

| Take: Extract raw materials | Reuse: Create from recycled and biobased materials |

| Make: Mass-produce garments | Make: Produce on-demand only and repair for longevity |

| Waste: Discard worn garments in landfills | Recycle: Transform worn garments into new materials |

The circular model of our textile services

Producing only what you need

The textile industry generates 92 million tonnes of waste each year, mostly from overproduction. By making garments based on customer demand, we avoid overproduction, reduce excess inventory, and minimise waste from the start.

Recycling and minimising waste

Only 1% of used clothes globally are recycled into new garments, but we’re working to change that. By repairing and reusing garments, we prevent millions of kilos of unnecessary textile production. From recycling water during washing to optimising delivery routes, we conserve resources at every step.

Weaving a net-zero future

We’re cutting emissions year by year, with a goal to halve our greenhouse gas emissions by 2030 (compared to 2021 levels) and reach net zero across our value chain by 2050. Our targets are validated by the Science Based Targets initiative, ensuring they align with the latest climate science.

Technology and innovation

We use smart digital tools and real-time data to simplify the management of your textile services. It helps you keep a lean inventory, stay compliant, and boost productivity.

Digital monitoring solutions

Radio-frequency identification (RFID) technology gives each of our garments a digital identity so we can track its location, usage, wash cycles, and repairs in real time. It ensures traceability, hygiene and smooth circulation across even the most demanding environments.

Hygiene, safety and compliance

In highly regulated industries, hygiene and safety can’t be left to chance. Our RFID tracking and real-time monitoring help ensure every garment meets strict compliance standards. We handle everything from supply to laundry, repairs, and replacements.

The future of textiles

Tomorrow’s textiles are circular, smart, and sustainable—driven by clean energy, local production, and bio-based materials.

The rental revolution

Textile-as-a-service models are transforming how businesses think about their textile needs. Renting workwear, mats, industrial wipers, or other textiles instead of buying them gives you an efficient, compliant, and circular solution.

Why choose reusable workwear?

A study with Gaia Consulting found that increasing garment reusability can decrease the number of needed items by up to 67%.

This reduction translates to an annual saving of 2.2 kg of CO2 emissions per person, thanks to lower textile waste, decreased fabric and garment production, and reduced transportation across the supply chain.

End-to-end textile service

Our end-to-end services, including textile delivery, washing, maintenance, and repairs, makes it convenient for our customers to adopt circular economy principles as part of their business.

We also offer solutions for textile end-of-life scenarios, including recycling, upcycling, and downcycling.