Water recycling in Chennai with Nalco Water

We teamed up with Nalco Water, an Ecolab company and global leader in water and process management solutions, in 2022. The aim was to launch the “Aquaest” water recycling project at our laundry in Chennai, India. In just over a year, we recovered 74% of water at the plant. We also reduced our total freshwater usage in Chennai by 56%.

India is the largest user of groundwater and among the most water-stressed countries in the world. Across our 13 laundries in India, we wash thousands of kilograms of uniforms and workwear daily for various industries. We do this according to required safety qualities and standards like chemical resistance and hygiene. Our workwear and cleanroom services in Asia use 45% of Lindström Group’s total water consumption.

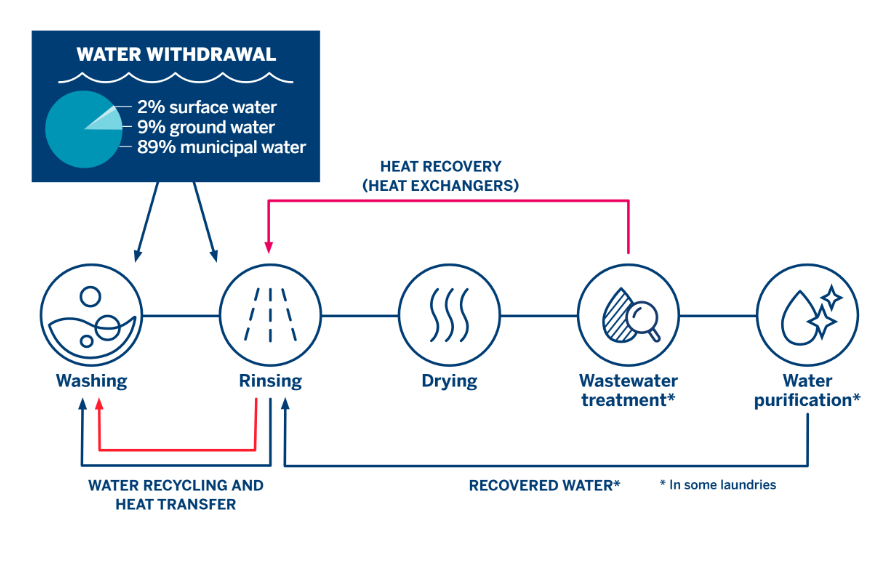

For decades, we’ve optimised water usage in our laundries in several ways. We ensure that we take care of wastewater in a responsible way. With water resources in India declining at an alarming rate, we continuously aim to expand our efforts to achieve the lowest possible water usage per washed kilogram.

“We already have a system for reusing water at our laundries. We wanted to take it further to recycle the water so that we could reduce the amount of freshwater we use,” says Venkataraj Anantharaman Laguduva, Head of Continuous Service, Asia at Lindström.

Targeting a 55% reduction in freshwater usage

The goal of the Aquaest project was twofold: to address water scarcity locally and contribute to global water sustainability efforts. Saving water is essential to preserve the environment, ensure sustainability, mitigate water scarcity, and contribute to global water equity for the benefit of current and future generations.

To kick off the project, we set specific targets and key performance indicators (KPIs) with Nalco Water to measure success:

- We aimed to recover 75% of water from the reverse osmosis process, and successfully reached 74% within 13 months.

- During the laundry process, we aimed to use at least 55% of recycled water. We successfully reached 56%—from 9.2 litres per kilogram to 4.1 litres per kilogram.

- We limited freshwater consumption by 44% in the washing process.

To reach these goals, we invested in a semi-automated wastewater treatment and reverse osmosis (RO) plant in Chennai.

“The water recycling project promotes the safe reuse of wastewater and water conservation in order to create a more sustainable water future for everyone. This project is a green solution for grey water pollution,” says Sabarinathan Muthukumarasamy, Production Manager at Lindström Chennai, India Unit.

Transparent collaboration for sustainable water management

Through our collaboration with Nalco Water, we work to ensure sustainable water management. Murli Iyer, Head of Light Business at Nalco Water, India, highlights the companies’ shared values: “Lindström’s commitment to sustainability, innovation, and the circular economy, along with their We Care culture, aligns harmoniously with Ecolab’s purpose of ‘Protecting what’s vital’. Also with our sustainability strategy: Advancing people, planet, and business health around the world, thereby helping our customers succeed.”

The water recycling plant, fully operated by Nalco Water, uses specialised chemicals for laundry detergent. This reduces water consumption without compromising the washing quality. Since both companies adhere to strict health and safety regulations, there have been no accidents or incidents throughout the entire project.

“The wastewater treatment plant, managed by Nalco, has effectively recycled the designated percentage of water. Thereby we significantly decrease the reliance on freshwater resources. Moreover, the treated water discharged into the environment meets the legal compliance standards of the region. It reflects the commitment to environmental responsibility,” says Nikhil Shirsat, Process Specialist at Lindström, Asia.

Nalco Water shares regular reports on a daily and monthly basis. We meet monthly to review progress and identify areas for improvement. After the first six months of the project, we also discussed what to focus on in the second stage.

“We’re both very transparent, cooperative, and collaborative. We trust each other. What I appreciate about Nalco Water is that they listen to their customers. Before saying no to something, they try as much as they can to make it possible.” says Venkataraj Anantharaman Laguduva, Head of Continuous Service, Asia at Lindström.

Substantial water savings and better wash quality

Our impressive results from the Aquaest project translate to potential annual water savings in our workwear and cleanroom operations equivalent to 330 million litres — or 132 Olympic swimming pools. In terms of daily water consumption, the initiative could offset the needs of 2.5 million people for one day.

By ensuring better water quality, we also enhance wash quality, reduce washing costs, and extend the life cycle of garments. The Aquaest project showcases our commitment to innovation and sustainability. It sets a benchmark for other companies to follow suit in proactive water conservation efforts.

“Lindström is setting the stage for other companies to do the same and be ahead of the times. The regulations for freshwater consumption in India and around the world are becoming increasingly strict. Companies might find themselves in a position where they suddenly need to lower the amount of water they use,” says Gowtham Raj, Area Manager – South at Nalco Water India.

Raghu Harihar, Training Manager, Institutional Business at Ecolab India, continues: “It’s great that Lindström is working with us to take these steps ahead of time — we aim to be thought leaders in the market to anticipate challenges before they occur.”

In the future, we plan to implement fully automated systems at the plant. This way we can further improve efficiency and consistency while minimising human error. We also aim to expand this RO system to other laundries in India and across Asia to decrease the stress on freshwater sources and provide more sustainable, cost-effective services.

An artificial intelligence (AI)-driven analytics platform, powered by ECOLAB3D™, will be the next step to advance the use of analytics and algorithms and further improve performance to accomplish even better results in water recycling at Lindström.