Simplify workwear with a digitally-supported solution

Managing workwear on your own can be surprisingly complex. Between buying garments, tracking stock, adjusting for temporary staff, managing sizes, and keeping up with repairs and cleaning, it’s a lot to handle.

That’s where our digitally-supported workwear rental service comes in. We take the hassle off your plate so you can focus on your core work. From recommending the right number of garments to tracking wash cycles and repairs, our service gives you data-driven insights that keep you in control—without the effort.

Heidi Tulensalo, Workwear Service Owner at Lindström, explains how our digitally-supported service works and the benefits it brings to customers.

Below you see how our service works. We take care of everything—so you don’t have to.

How data fuels our workwear service

Our workwear service uses data as the fuel to make garment management transparent, efficient, and hassle-free for your team.

Every one of the millions of garments we manage is RFID-tagged, allowing us to monitor, manage, and optimise the service with our customers. While no data system is perfect, we use actionable insights from garment usage to provide the best possible service.

Heidi Tulensalo, Workwear Service Owner

The RFID tags, combined with multiple scanning points, create a detailed map of each garment’s journey. Regular scanning adds transparency to the process, helping us quantify our work, fine-tune our operations, and improve product design. When garments reach the end of their life and get recycled for a new one, for example, the data gives us insights into wear patterns, which helps inform pricing and product improvements.

RFID tags have made it possible to add new tech to our workwear service, like the award-winning Workwear Flex lending station for non-personalised garments.

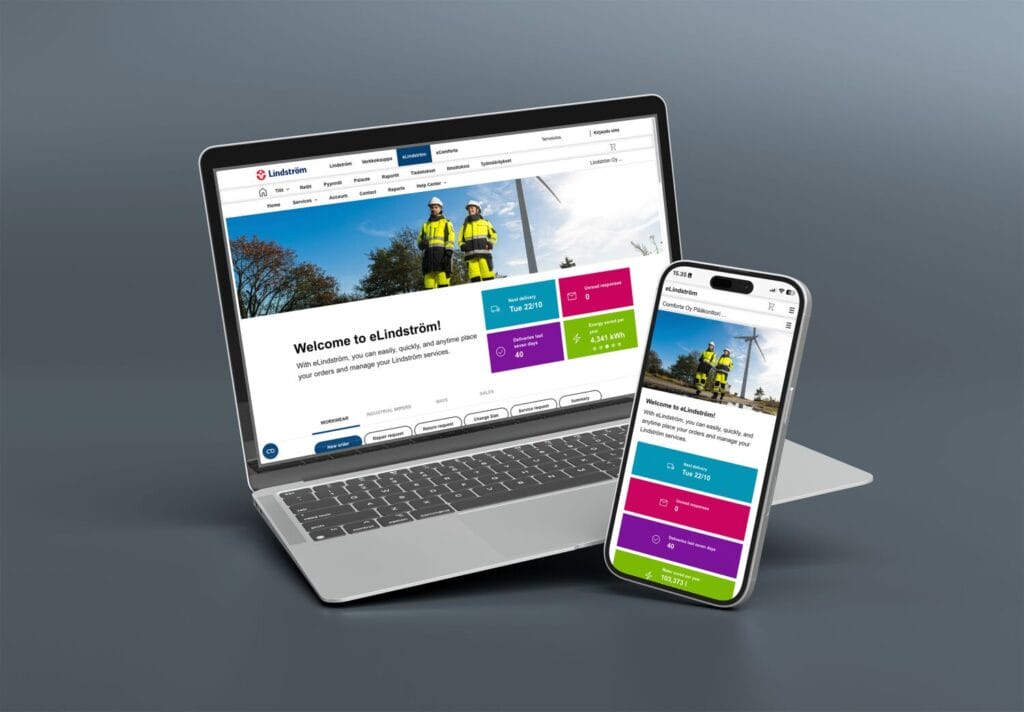

This transparency also lets us share precise updates with you—whether it’s tracking down a missing pair of trousers or giving real-time updates on a garment. You can easily follow and manage your workwear service in eLindström, our online platform, without needing to pick up the phone.

Top benefits of digitally-supported workwear

Keep a lean inventory

Real-time data makes it easy to stay on top of your workwear needs. You can identify when you have surplus stock and when it’s time to order more garments.

While our dashboard gives you visibility into your workwear inventory, managing physical garments goes beyond just monitoring data. Keeping a lean inventory means taking timely, decisive action. You get the insights you need in eLindström to make the right choices for your workwear inventory.

Meet health & safety requirements

In regulated industries like food, healthcare, and pharmaceuticals, workwear is about more than just protecting employees—it’s also about protecting the products and people you work with. Using a professional workwear service guarantees that your workwear is cleaned and maintained to meet strict regulatory hygiene standards—something washing at home can’t guarantee.

Proper maintenance is also crucial in specialised fields like electronics and welding, where ESD-coated workwear prevents safety hazards.

We track every garment’s journey to ensure it’s regularly serviced and up to protective standards. This not only ensures compliance during audits but also gives you peace of mind that safety is always covered.

Heidi Tulensalo, Workwear Service Owner

Boost productivity

With the right workwear always available, you won’t need to pause production or worry about garment logistics. “We handle textile management so you can focus on your core work,” says Heidi.

Our new Workwear Optimal tool—an add-on service in eLindström—helps you get even more out of our service. It offers a “regular health check” for your workwear by providing recommendations on which garments need attention and identifying potential risks for the optimal set of garments, based on the data we gather throughout the service cycle.

In early pilots, customers discovered useful insights to improve efficiency. Heidi shares an example:

You might have a set that includes T-shirts, but they’re not being used because your employees prefer long-sleeve shirts instead.

Another pilot customer discovered some garments weren’t in circulation because employees had taken them outside the factory. “It’s not always about identifying excess pieces, but about behaviour. Do you need more garments, or should we do more employee training?” says Heidi.

By addressing these issues, you can ensure better workwear usage and improve overall productivity.

The future of workwear is more than just garments

Workwear Optimal is just the beginning of what digitally-supported workwear can achieve. As we integrate data more deeply into our service, it becomes a core part of what we offer—not just an add-on.

Our goal is to create value at every stage of our customers’ journey, using data to optimise operations, maximise service value, and minimise our environmental impact. We’re always looking for new ways of using data to solve customers’ challenges in a way that also positively impacts our business and the planet.

“What if our workwear service is more than just our garments? That’s where I hope we’re headed in the future—using workwear data to improve customer operations in new ways,” concludes Heidi.