Textile recycling

Recycling matters

Our circular business model prevents and reduces the creation of textile waste in many ways. Still, textiles are one of our most significant waste streams. That’s why, we have set an ambitious goal to recycle 100% of our textile waste by the end of 2025. Here are three ways in which we ensure that your textile service is maintained with optimised resources.

Using resources efficiently in every step

Optimising our use of water, energy, detergents and raw materials throughout our business operations.

Cutting emissions and closing the loop

Our next step is simple but bold: turn every end-of-life textile into new raw material by 2025.

Recycling textiles and using recycled materials

Thanks to new partnerships, 70 % of the textiles we remove from service now find a new life.

1. Using resources efficiently

We optimise laundry processes to reduce the use of water, energy, and detergents. Here’s how it works:

Textiles with a long lifespan

When using materials and products efficiently, and for a long time, we ultimately need fewer resources.

Our waste hierarchy guides us in handling the eliminated textiles in order of priority.

Recycling

The lack of recycling solutions is still a significant challenge where we constantly look for new solutions. Local markets are still in a different development phase regarding recycling solutions, and we must always weigh the benefits of recycling against the burden of transporting waste longer distances.

Regulations

Regulators and authorities are setting requirements and supporting textile waste recycling. For instance, the European Union’s strategy for sustainable textiles requires textiles to be designed for circularity, promoting reusability and recyclability. This helps to drive the industry standards forward.

2. Cutting emissions and closing the loop

We have a long history of increasing energy efficiency, optimising our customer deliveries, and reducing the overproduction of textiles, all of which impact our emissions. Committing to net-zero emissions was a natural next step on our journey towards more sustainable services. It supports the common target of preserving a livable planet for future generations.

Many of our customers share the same values and invest in improving their sustainability. Therefore, we believe it is also crucial to our business continuity to provide them with services that help them reduce their environmental burden.

Sustainability achievements we're proud of:

We can't do it on our own

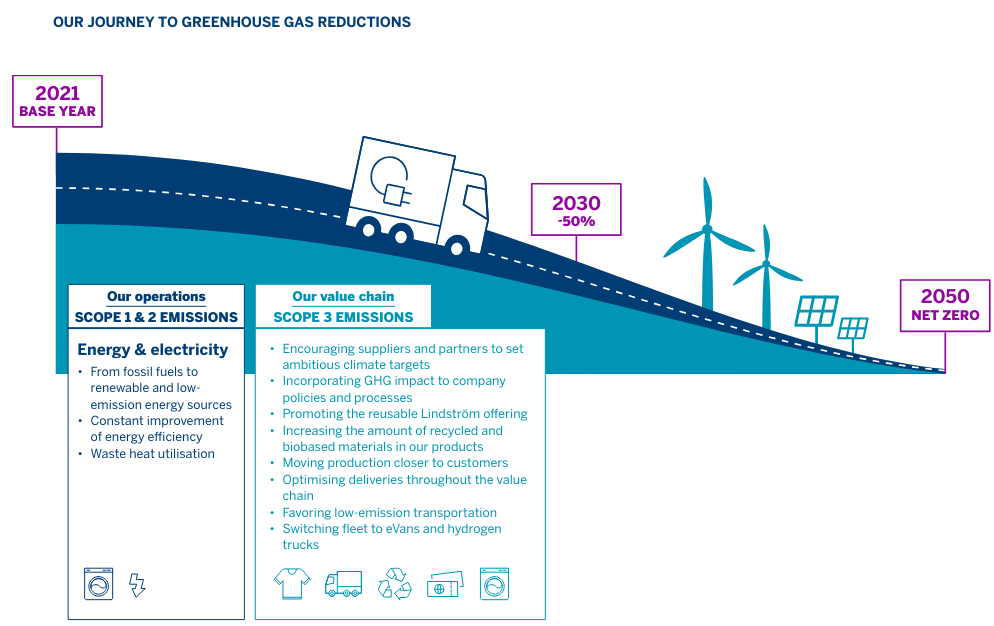

Most of our greenhouse gas emissions are caused in the value chain. Therefore, it is important to engage our suppliers and partners. We encourage setting ambitious climate targets and acting towards them.

Our net-zero commitment drives our supplier collaboration and we discuss the topics with our customers and support their climate targets. From autumn 2022 to spring 2023, we took part in the SDG Ambition Accelerator programme, arranged by the United Nations Global Compact initiative in the Nordics. In this six-month learning journey with peer companies, we focused especially on Sustainable Development Goal 13, Climate Action, and how to ensure business transition towards a 1.5 °C pathway.

Reaching sustainability goals isn't a straight path

Complex garment designs, limited recycling technologies and the need for reliable end-users of secondary fibres all slow things down. That’s why we’re deepening R&D partnerships in Europe and India to tackle hard-to-recycle items such as industrial wipers and multi-component workwear.

In Finland and the Baltics, our teams are gradually transitioning to renewable diesel which can reduce greenhouse gas emissions by up to 90%.

Net-zero laundry program is one of our key initiatives to significantly reduce the greenhouse gas emissions from our operations.

Net-zero target approved by SBTi

Guided by our purpose, we have made a commitment that will guide our decisions for the coming decades. We aim to halve our absolute greenhouse gas emissions by 2030. Furthermore, to reach net zero by 2050 across our value chain.

In June 2023, our targets were validated by the Science Based Targets initiative. This ensures that the goals are aligned with the latest climate science. Lindström can be considered one of the forerunners and the net-zero target ambitious. At the time of target validation, there were only 260 companies in the world with the SBTi-approved, science-based net-zero target.

Reaching the target requires a lot of work, investments, and innovation. As our own operations form only about a quarter of our total carbon footprint, it’s crucial to work together with stakeholders in our value chain.

3. Recycling textiles and using recycled materials

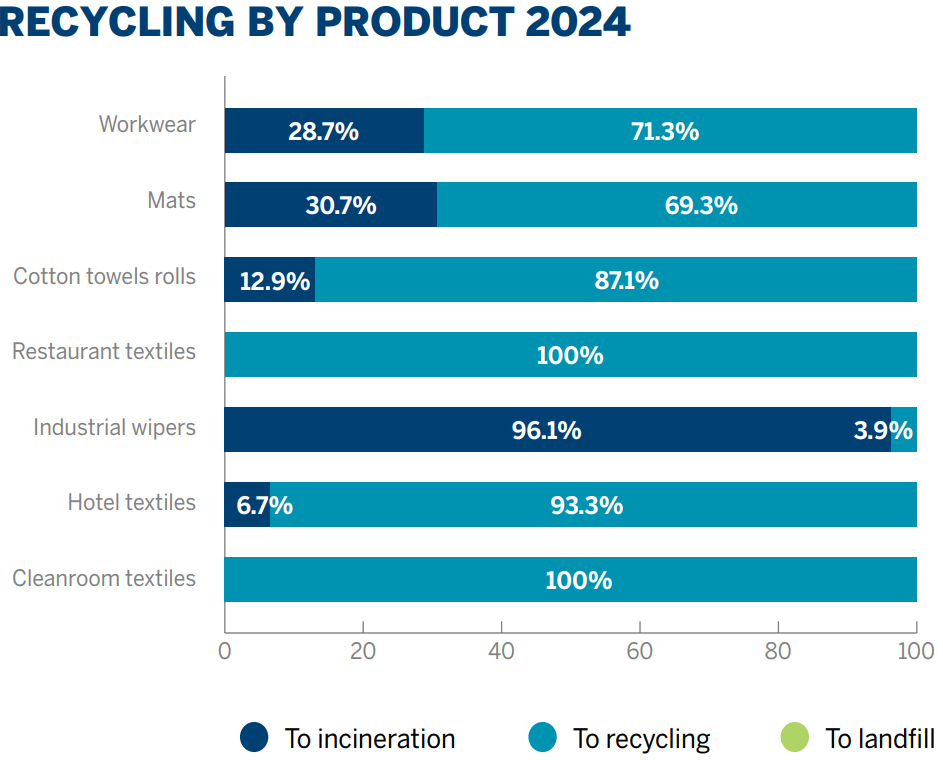

We strive to recycle 100% of our textile waste by the end of 2025.

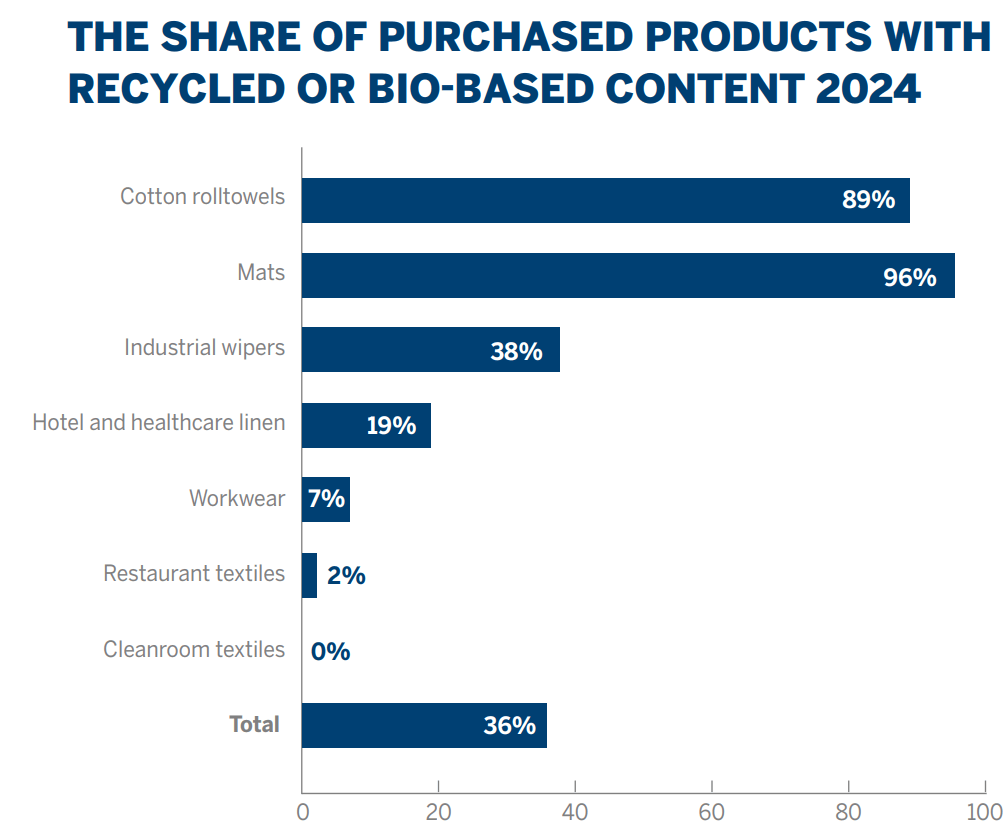

Thanks to new partnerships, 70 % of the textiles we remove from service now find a new life. Our standard mats already contain 75 % recycled fibres.

Not only do we seek to reduce the amount of waste. We also need to decrease the need to use virgin materials. Many different industries can use textile waste as raw material, including the textile industry itself. Our bold aim is to close the loop, using end-of-life textiles as raw material for new textiles.

The recycling rate and the amount of recycled fibre used in our new products vary quite a lot between service lines. As we increase the amount of recycled fibres, we must find a balance that does not compromise their durability.

To reduce emissions and provide our customers with more sustainable textile solutions, we are committed to increasing the number of purchased materials using recycled and bio-based fibres. We set a 30 % goal for 2025 and hit 36 % already in 2024.

Making the most out of existing materials: 3 examples