Unravelling the cotton towel roll’s environmental impact

A new study measures the carbon footprint and water consumption of our cotton towel rolls from field to recycling. The life cycle assessment provides important data for optimisation and helps our customers make more sustainable choices.*

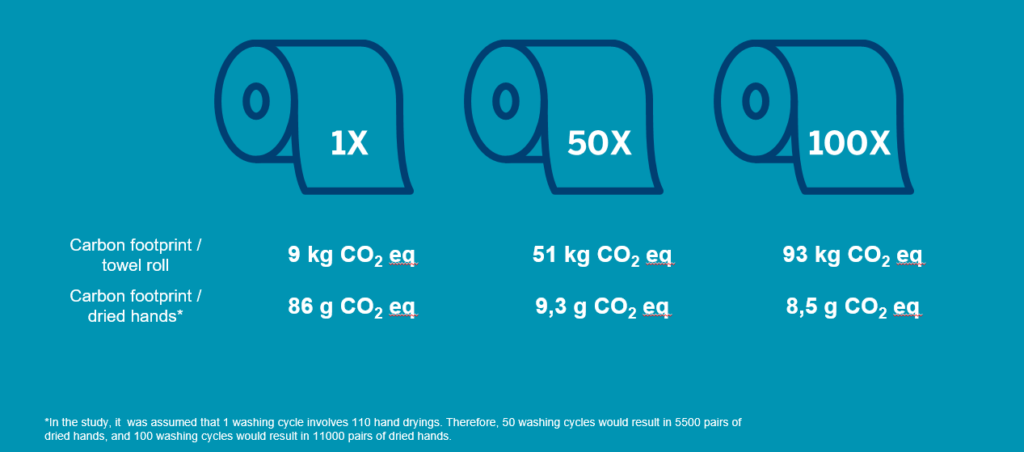

What’s the carbon footprint of a cotton towel roll over its life cycle? Does the footprint look different after one, 50 or 100 washes? How does it compare to drying your hands with a paper towel? These were some of the questions we wanted to answer with a product-specific life cycle assessment of our cotton towel rolls.

The goal for the study, conducted by Gaia Consulting, was to get a clear picture of the CO2 emissions and water usage throughout the entire supply chain and enable customers to make a more informed choice, explains Terhi Hasila, Service Owner at Lindström.

“This assessment confirms that we have been doing the right things so far; optimising all stages of the cotton towel roll’s life cycle, making sure it can be used multiple times, and pushing recycling capabilities.”

*The results include only the fossil CO2 emissions. Biogenic and land-use change emissions were not included. Also, the results do not include the CO2 emissions for the dispensers and other products of our Washroom Service’s collection.

Raw materials and manufacturing have the biggest impact

Assessing the entire life cycle of a cotton towel roll, from field to factory and transportation to recycling, is not an easy feat. But looking at the entire supply chain is the only way to form a comprehensive picture and focus efforts on stages where the carbon dioxide emissions or water usage – and thus room for improvement – are the biggest.

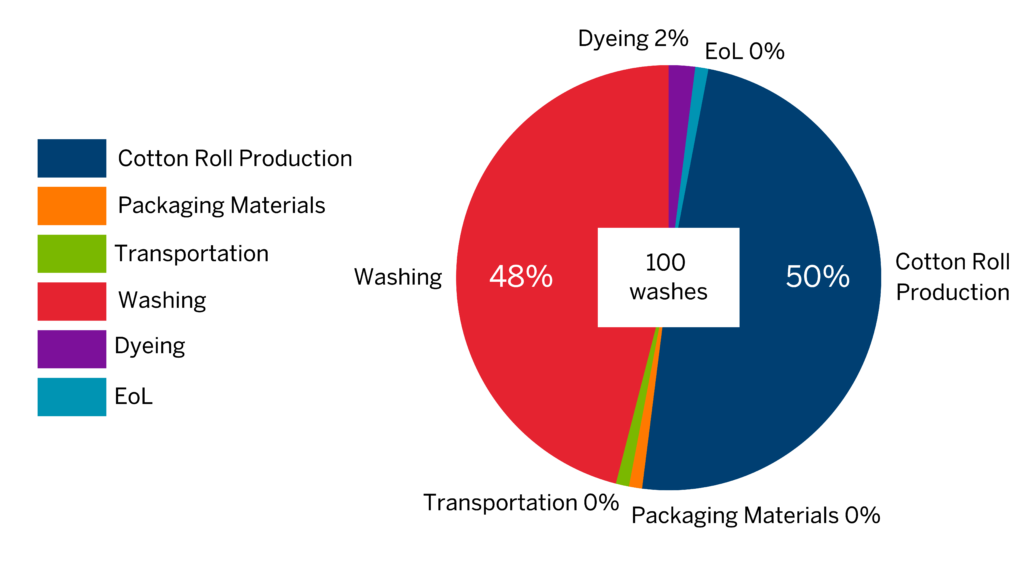

“For example, even though it may feel counterintuitive, the role of delivery is relatively small. The roll is driven back and forth up to hundreds of times, so it feels like it should have a big impact on the carbon footprint, while in fact, its impact is quite small,” Hasila explains.

Delivery accounts for only 3% of a towel roll’s carbon footprint. It doesn’t mean there isn’t room for optimisation in the delivery stage, such as preferring electric vehicles or bio-based fuels, but data helps to put things in perspective.

Raw materials and manufacturing have the biggest impact on both CO2 emissions and water usage. If a cotton towel roll is washed only once, the raw materials account for a whopping 69% of its carbon footprint, while they are only 8% if the roll is washed a hundred times. Considering that the raw materials are exactly the same regardless of the number of washes, it’s the longevity of the roll that makes a big difference.

And the same goes for water usage. The assessment shows that the production stage still accounts for 50% of the overall water consumption even after a hundred washes.

Cotton deserves respect and recycling capabilities.

The assessment shows that we should respect cotton more, Hasila says. Farming and manufacturing require plenty of resources, so it should be ensured that the precious material gets the long life it deserves.

“We should treat cotton as a material as if it were the finest silk. Reusing it time and time again as a hand towel is exactly the right kind of use for cotton, not turning it into a fast fashion T-shirt that might be tossed away after just one use.”

A single cotton towel roll can be washed and reused 100 times, that equals around 20,000 paper towels – or up to 72 kilograms of paper. Whereas paper towels usually end up in a landfill, the cotton towel roll can have a second life once it’s served its purpose.

Today, over 80% of our cotton towel rolls are recycled as new products or fibres. However, the challenge is that the capabilities for manufacturing and utilising recycled fibres are still relatively small, Hasila explains.

“We’re lacking an industrial scale closed-loop model where materials are recycled again and again.”

Our goal is to use more recycled cotton in the towel rolls, but using recycled fibres has limitations. When cotton is recycled, its fibres get shorter, reducing tensile strength and abrasion resistance, two important features of a high-quality cotton towel roll. Thus, finding the most sustainable product requires balancing different qualities and constant optimisation.

“There’s a limit to how much we can use recycled fibre, as it shortens the towel’s life cycle, which in turn isn’t sustainable.”

While some challenges, like developing industrial-scale recycling capabilities, are large and complex, there are also some surprisingly simple ways to increase the recyclability of a cotton towel roll. If the rolls are taken out of their dispensers too early and sent back for washing carelessly, chances are that the over 30-metre rolls get so tangled up that washing and recycling them is impossible. Changing the roll at the right time is the simplest way to reach 100% recyclability.

“Our smart technology notifies the staff when it’s time to change the roll, ensuring that the user doesn’t have to dry their hands on their trousers and helping our customers use the entire roll. The idea of the Smart Washroom Service is to save time, money, and resources and increase sustainability while doing it.”

Assessment is a snapshot

Hasila emphasises that a life cycle assessment is always a snapshot of a specific point in time. As manufacturing facilities transition to renewable energy and recycling capabilities improve, the picture will be very different in years to come.

Even though sustainability has become a prerequisite for many businesses and the markets want to compare products head-to-head, Hasila points out that calculating carbon footprint or water consumption is still partly based on best estimates. Comparing products is challenging due to different methodologies.

“This assessment is just phase one. We need to push to get transparent reporting from across the value chain, as it makes our calculations more accurate.”

In the future, Hasila envisions an assessment for the entire washroom service, from dispensers to hand sanitisers. But if assessing just the towel roll is a challenge, then taking plastics, chemicals and minerals into account lifts the complexity to a whole new level.

In the meantime, Hasila sees the product-specific CO2 measurement as a starting point for continuous optimisation and a call for a supply chain-wide discussion.

“We want to help our customers make a more informed choice and ensure our suppliers commit to sustainable activities. That’s why we must engage the entire supply chain in this conversation.”